FEEDER BELTS

Coal Feeder or Gravimetric Feeder Belts

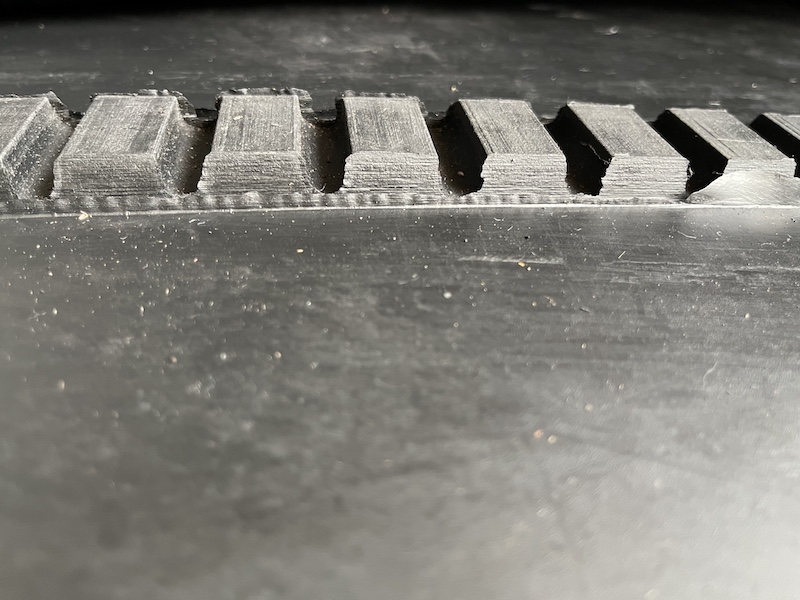

WITH INTEGRATED SIDEWALLS

Dynamic Rubbers Coal Feeder or Gravimetric Feeder Belts are employed in Thermal Power Plants and Coal Handling Plants. These belts come with Collars or sidewalls to limit or avoid spillage of material.