Rubber Sheet

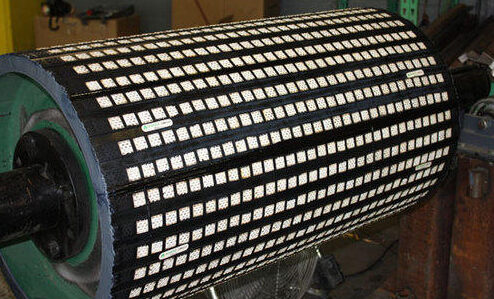

Ceramic Pulley Lagging Sheet

REACH, RoHS, PAH and CE certified

The chloroprene bonding layer on Dynamic Rubbers Ceramic Lagging Sheets is utilized as a protective covering to maximize pulley life in applications for harsh circumstances, for instance: damp and muddy environments.