PACKING UNIT BELTS

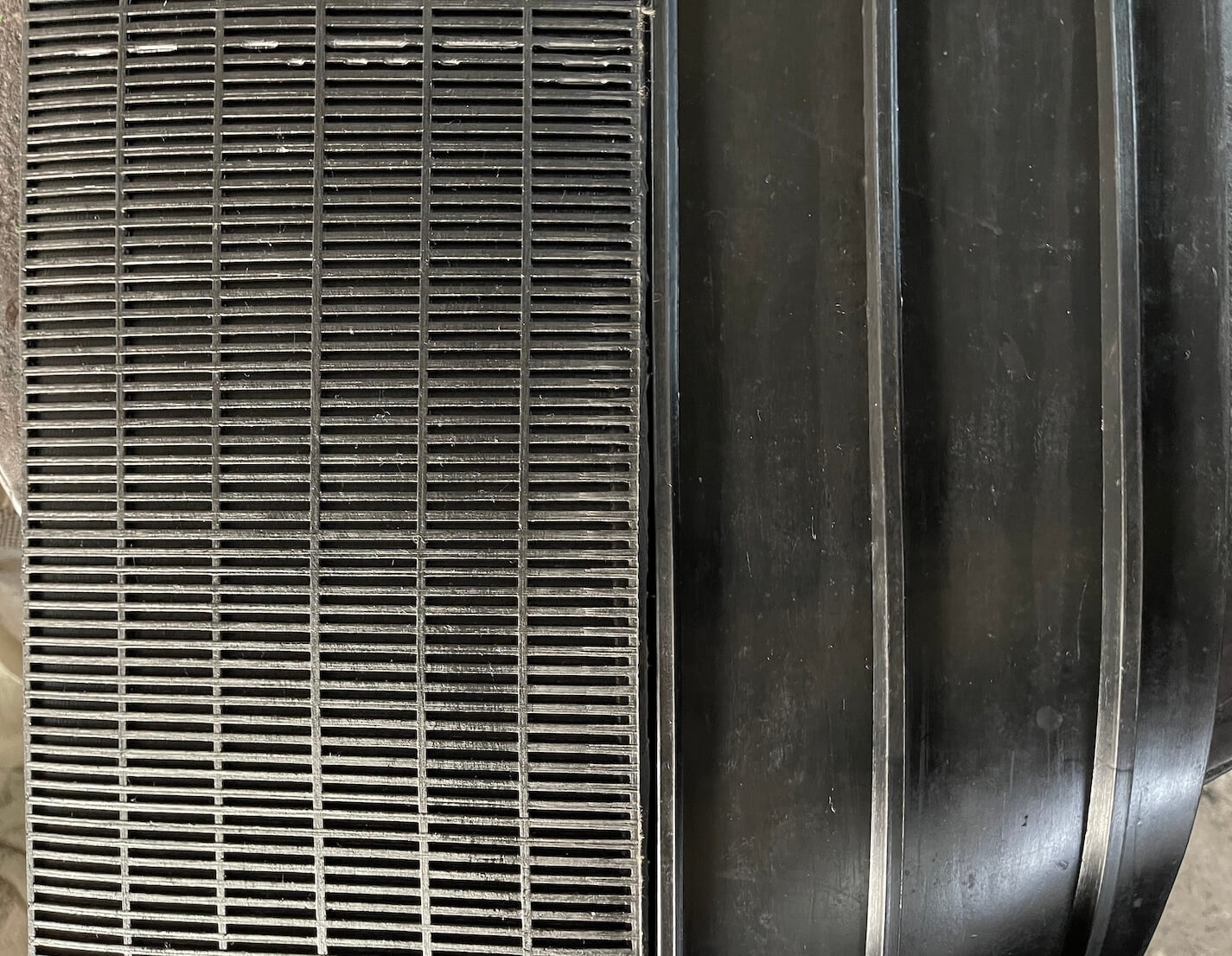

Bag Diverter Belts

TRULY ‘ENDLESS’ BELTS

The Dynamic Rubbers Bag Diverter Belts were designed to redirect packed units/bags by means of a high-speed mainline conveyor belt. Bag diverting is an efficient material handling method..